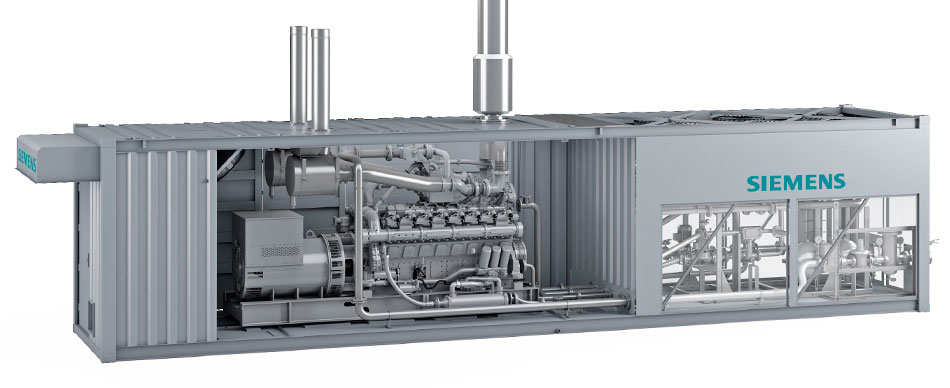

Container type

GPG Siemens

|

Container gas gensets are fully prefabricated and require minimum assembling works on a site. Gas piston gensets have the advantages in comparison with placing on the skid or bulk supply in a building:

-

Gas genset in a container is a fully designed and prefabricated block of a packaging factory.

-

A customer gets a fully prefabricated power generating system which requires only connection to heating, gas pipelines, power and signal cables during assembling works. This considerably reduces the time needed for starting the operation.

-

Production of gas genset containers with integrated engineering systems allows to reduce the time of equipment supply due to block principle of layout.

-

The clients are given possibilities to participate in an equipment test in the factory.

-

A customer gets all the systems of the container ready in full accordance with technical requirements of the European and Russian standards, i.e. ISO-9001, ISO-14001, GOST, permissions of the Federal Environmental, Industrial and Nuclear Supervision Service of Russia.

-

Reinforced frame of the container with wide side gates helps the service process of the container gas genset and gives an access to auxiliary equipment without dismantling of the container walls.

-

All containers are supplied with lifting equipment, i.e. with a telpher or hoist which makes the process of service and overhaul more convenient.

-

Gas genset containers have separated and isolated compartments for both: the control panel and power panel.

The models of gas engines for operation with natural gas

| Model | Power

electr. (kW) |

Gas engine |

| SGE-18SL | 303 | L6 |

| SGE-24SL | 404 | L8 |

| SGE-24HM | 501 | L8 |

| SGE-36SL | 610 | V12 |

| SGE-48SL | 811 | V16 |

| SGE-56SL | 954 | V16 |

| SGE-56SL/40 | 1001 | V16 |

| SGE‐42HM | 1011 | V16 |

| SGE-56HM | 1204 | V16 |

| SGE-56HM Plus | 1315 | V16 |

| SGE-86EM | 2011 | V12 |

It should be taken into account that with electrical power of 1000 kW a customer can get around 1000 kW useful thermal energy if the gas genset is equipped with a heat recovery system.

The current fifth generation of gas engines for operation with natural gas allowed to reach electrical efficiency at 45%. Their efficiency is a few percent higher than of the biggest steam turbine sets of condensation type. At the moment gas engine of the sixth generation is being developed. Herewith all existing models of gas engines are able to operate with natural, associated oil gas and use propane-butane mix as a reserve fuel.

Gas turbine power plants

Solar Turbines

Catalogue Solar Turbines – pdf

|

Spare parts for steam and gas turbines

In cooperation with the partners Volante Russia supplies spare parts for steam and gas turbines of different power range Т-250/300-240, Т-100-130, Т-110/120-130, Т-50/60-8,8, Р-50 Ural Turbine Works and gas turbines (GTT-12, GTT-3M, General Electric MS5002E, Siemens SGT5-2000E):

– rotor blades, guide vanes, sets of blades and segments of blade bandages;

– nozzle/guide vane disks, diaphragms;

– sealing rings;

– disks of turbines, rotor disks;

– rotors;

– check valves, control valves;

– axle boxes, axle rods;

– segments of damper wires;

– rivet blanks;

– springs;

– housing studs, nuts, sleeves;

– cast turbine details of the European manufacturers.